Chiyozuru Korehide

Chiyozuru Korehide

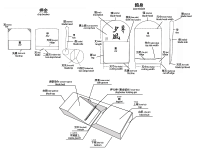

鉋 Kanna

「尖れたる鋒(きつさき)、形槍のごとし、また短矛に似たり」『和漢三才図会』

棒状の柄の先に柳のような剣のような両刃の刃を取り付けたものがかつては「カンナ」と呼ばれ、材の表面を削りとる道具として古墳時代から中世まで使われていました。古くは弥生時代にも存在した痕跡があり中国にも存在しない日本固有の道具です。これらは現代では「ヤリガンナ」と呼ばれています。

そして現在の「台鉋」は大陸から日本に渡ってきました。しかしこの時の使い方は「推して」使うものでした。「引いて」使うようになったのは江戸時代中期。木の表面を美しく仕上げる日本の風土、美意識がそうさせたのかもしれません。

The Japanese kanna (plane) was described in 1712 in the Illustrated Sino-Japanese Encyclopedia as similar to a short spear or lance.

The word kanna was originally used to describe a tool made of a double-edged blade attached at an angle to the tip of a pole-shaped handle. This tool was used from the Kofun period until the Middle Ages as a tool for planing material surfaces. Archaeological evidence also suggests this kind of kanna native to Japan was used as far back as the Yayoi period. These tools are referred to today as yari-ganna.

The kanna in use today, which is also called dai-ganna (iron and steel blade set in a wood base), came to Japan from the Asian continent. Kanna were originally pushed across the surface of the wood away from the woodworker. The transition to pulling the plane toward the woodworker, as kanna are used today, occurred in the middle of the Edo period. This change may have been driven by the specific cultural and aesthetic sensibility in Japan that values beautiful wood surface finishes.

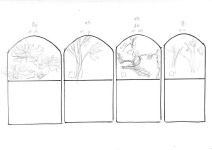

想 Feeling

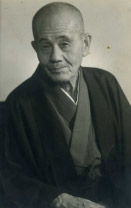

「やぁ~だね。弟子になればわしと同じように一生貧乏するからあきらめて播州に帰りなさい。」

鉋鍛冶の道を歩み始めた18歳の神吉義良は大阪で是秀の作った鉋に出会い、衝撃を受けた。

家族の反対を受けながら半ば家出のように上京。弟子入りを志願する義良に是秀師は言った。

それでも日本一の鍛冶屋をめざす義良はあきらめなかった。時には川の水を飲み、関東の鍛冶屋で転々と働きながらも日参する日々が始まる。

時は昭和3年。不景気のどん底。

“That’s no good. If you apprentice with me, you’ll live your life in poverty like I have. Give up and go back home to Banshu.”

At the age of 18, Kanki Yoshiryo, who had already set out on the path of bladesmithing, encountered in Osaka a kanna (plane) made by Chiyozuru and was utterly captivated.

Over his family’s objections, Kanki snuck out of the house and set off for Tokyo. Once there, Korehide refused his request to take him on as an apprentice.

Despite the initial rejection, Kanki continued to pursue his dream of becoming the best bladesmith in Japan. So began his days of working at bladesmiths across the Kanto region, while continuing to entreat the master. At times, the would-be apprentice’s pockets were so empty he was forced to drink water from the river.

The year was 1928, and the economy was in the depths of a depression.

-

千代鶴是秀 Chiyozuru Korehide -

千代鶴貞秀 Chiyozuru Sadahide -

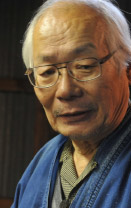

二代目千代鶴貞秀 Chiyozuru Sadahide II

郷 Home Town, Miki City

古くは天目一箇命(あまのまひとつのみこと)を祖神とする氏族が鍛冶技術を育んでいました。

これを「大和鍛冶(やまとかじ)」」と呼んでいます。 そこに、百済から聖明王の王子、恵が帰化した時に

大陸系の「韓鍛冶(かんかじ)」の技術が融合し技術は飛躍的に進化しました。三木の地は

西方に中国山脈の砂鉄、東方に丹生山の朱土を産出し、屯倉(大和朝廷の直轄領)が置かれ

その首長に鍛冶技術集団の首長を任命するほど重要な場所でした。

Japanese bladesmithing techniques were cultivated in ancient Japan by a clan who worshipped the blacksmith deity Amanomahitotsu no mikoto.

They were called Yamato kaji, or Japanese blacksmiths. When Prince Kei from the ancient Korean kingdom of Baekje immigrated to Japan, Korean blacksmithing techniques that originally developed on the Asian continent were integrated into Yamato kaji, and Japanese blacksmithing evolved dramatically.

With access to the iron sand of the Chugoku mountains to the west and the cinnabar of Mt. Niuyama to the east, the Miki City area became extremely important to the blacksmithing industry. So much so that the territory was put under direct control of the Yamato Imperial Court, and the chairman of the association of craftsmen was appointed to be district chief.

三木市の紹介を見る

(外部リンク)

Learn about Miki City

(link to external page)

その後戦国時代には別所長治の治めるころから三木町を免租地とし、羽柴秀吉による三木城攻めで

別所氏が滅びた後も秀吉により地子免許状が出され、2年にわたる三木城攻めにより流出した人民を

呼び戻しました。その結果、多くの大工がこの地に集まり、その大工道具を作る鍛冶職人も急増し

現在の三木の基礎が出来上がりました。

そして三木から地方に出稼ぎの大工が三木の道具を持っていき、その切れ味のよさが地方の職人に伝わり、

流通の便も時代の変遷により次第に良くなっていったことから、全国に三木金物の良さが広がっていきました。

平成8年には「播州三木打刃物」として鋸、鏝、鑿、鉋、小刀が国の伝統的工芸品の指定を受け、三木市で生産されるその他の多種多様な工具に於いてもさらなる技術の進歩と新製品の開発に力を入れ発展しています。

The village of Miki was later designated a tax-exempt land around the time that the daimyo Bessho Nagaharu ruled the area during the Sengoku period. After defeating Bessho in the siege of Miki Castle, Hashiba Hideyoshi issued a certificate that would allow the manor to collect land rent from farmers, and villagers who had fled during the two-year siege returned. The area became home to a large number of carpenters, and the number of blacksmiths forging carpentry tools surged, as well. With these developments, the foundation for the Miki City of today was established.

When the carpenters left the area for other parts of Japan, they took with them the tools made in Miki, and the superior cut of the Banshu Miki blade became known to craftsmen in other areas of the country. As Japan developed better distribution systems, the superiority of Miki ironware became known throughout the country.

In 1996, the Japanese government designated Banshu Miki blades in saws, irons, chisels, kanna (planes), and kogatana (craft knives) as traditional crafts. Miki City is focused on developing new products, as well as on advancing techniques in an array of other types of tools produced in the area.

挑 Challenge

「先人の技術に現代の感覚を融合する。その積み重ねが新たな技術の種となる。」

鉄本来の美しさを追求するため、新しいデザイン、製作方法にも挑戦していきます。

そしてその積み重ねが次の時代へ引き継ぐ原動力になると信じて。

“Integrating traditional techniques handed down over generations with a modern sensibility is an exciting challenge. It is in the repeated attempts to achieve this that new techniques are born.”

Our endeavors to develop new designs and forging techniques are driven by our pursuit of the inherent beauty of iron and steel.

And we believe that our pursuit of this beauty will provide the motivation for the next generation to embrace these same challenges.